Providing Energy: From Supply Security to Energy Sovereignty

The advent of individual comfort has made us forget how, for centuries, private needs were not a priority and received little innovation. When caminology—the science of chimneys—experienced a technical revolution in the 1750s with the elevated and narrowed hearth, the energy efficiency of chimneys, or fireplaces doubled to a meager 15 percent. Industry, particularly arsenals and forges, was prioritized, and cold was a common experience, even for the affluent. Energy sovereignty was no longer a priority by the 1980s, thanks to the use of resources from friendly countries and geographic diversification of supply sources ensuring the stability of the global market. However, the war-induced ecology caused by the conflict in Ukraine has brought back forgotten questions that are unlikely to disappear, even if the growth of global needs contradicts the imperatives of climate change.

Grégory Quenet

With the first industrial revolution, the development of our modern societies was made possible by access to coal, an energy source that was more abundant and less costly than previous ones such as water, wood, and horses. This transition to a radically new world first occurred to address supply difficulties: the wood crisis, driven by population growth and increased needs, accelerated the use of “charcoal from the earth,” or fossil charcoal: coal. Historian Fernand Braudel recounts in L'Identité de la France:1 “Our forests, although abundant, could not withstand intensive exploitation: wood was used for heating houses, cooking, and, in the form of charcoal, for the production of cast iron, iron, and steel. It was also an essential material for clog makers, woodworkers, and the construction of cars, plows, and houses, as well as boats and ships. Blast furnaces, forges, and foundries were not the only ‘fire factories’—we must also include glassworks, breweries, and lime kilns.” Moreover, for the historian, if England “used stone coal early on, even just for heating London, and if it proved to be a pioneer in the use of coke, it is partly because it was forced to do so due to the depletion of its forest resources.” The decrease in the cost of coal only came later—and it then surpassed wood before being joined by oil and gas. However, let us retain the essential point from this original moment: it is a need that, once again, before technology or even cost, became the primary driving force behind technological and social development.

Even in an era of abundance, the importance of securing the energy supply has not disappeared; on the contrary, it has become more pronounced in response to needs considered increasingly essential and on which society's life has become more dependent. This attention is particularly evident in countries that are less well-endowed with fossil resources, such as France, an importer of coal and later of gas and oil, or countries in Eastern Europe, whose energy dependence on oil or gas-producing countries remains strong even today.

Before shifting to address energy savings or concerns about decarbonizing the energy mix to contribute to the fight against climate change, it was primarily the need to ensure the security of the energy supply and continuity of service that was at the heart of users’ concerns. It is within this context that Veolia's first expertise was developed.

Heating Buildings and Populations: A Challenge of Modern Comfort

Today, so-called “energy performance contracts” are well-known, although not always adopted. Their purpose is to “improve the energy performance of a building through investments in renovations, supplies, or services.” Such contracts are made between a company or a municipality and an energy service company. The service provider commits to specific energy consumption goals, which are measured and monitored over time. In reality, such contracts are not so new. In 1935, Léon Dewailly created Chauffage Service, a company specialized in the operation of heating and air conditioning systems. Two years later, on Christmas Eve, Léon Dewailly received a call from the director of the hospital in Villiers-Saint-Denis in Aisne.

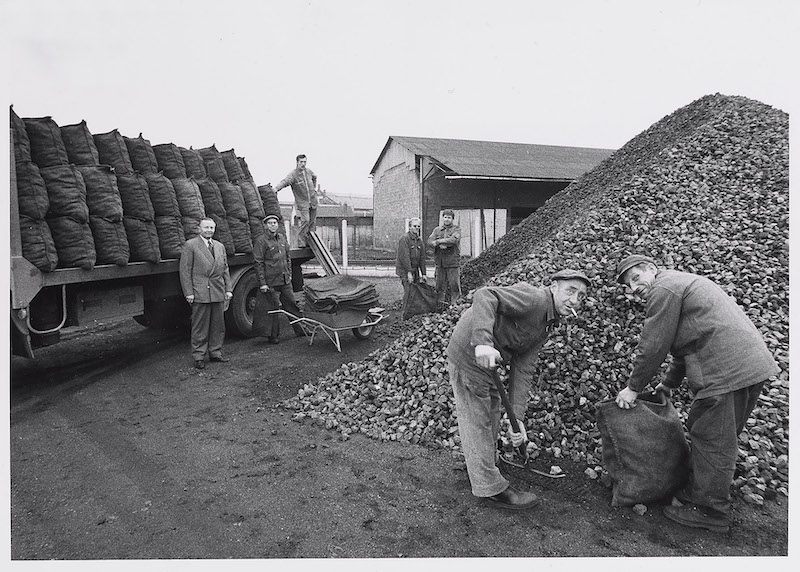

The coal-fired boiler was not working, and the cold was infiltrating the facility. “The on-site teams couldn't fix it,” says Patrick Hasbroucq, director of industrial units in the Hauts-de-France region, "so Léon got in his car and drove to the hospital to fix the unit. The director was very satisfied with the repair and asked him to ensure the continued operation and maintenance of the equipment through a contract guaranteeing a defined temperature.” This was the first-ever energy performance contract signed. It was a heating contract that would subsequently serve as a reference, known as “P1, P2, P3,” covering energy supply and operation and maintenance of installations, as well as equipment renewal. Supply security and service continuity were at the heart of the promise of this new company in tune with the times.

Léon Dewailly would make his business thrive, and it became the Compagnie Générale de Chauffe (CGC) after World War II. As a visionary entrepreneur, he innovated and relied on new multi-service contracts offered to certain clients, such as NATO bases. However, it was the boom in collective housing construction in France during the Trente Glorieuses (the post-WWII French economic boom) that allowed him to develop his business. At that time, heating became a new requirement for the comfort of a home, whereas in the past, a coal stove in the living room was often considered sufficient.

From the harsh winter of 1954 onwards, Abbé Pierre's fight against substandard housing made domestic heating a major social issue. A gas heating boom followed: water heaters, boilers, stoves, and radiators all contributed to gas consumption in households. This growth began during the interwar period but gained momentum after World War II, while electricity still suffered from high tariffs and a lack of adequate infrastructure. As academic Jean-Pierre Williot writes, “Far from succumbing to electric competition, the gas industry claimed to be at the forefront of a movement promoting domestic comfort.”2 In 1946, 76 percent of gas consumption was due to domestic use, ahead of commercial and industrial use (8.7 percent).

Even though 60 percent of French homes still did not have central heating by the early 1960s, some major cities already had district heating networks before World War II (Paris in 1927, followed by Chambéry, Villeurbanne, Grenoble, and Strasbourg)3. But really, it was the Trente Glorieuses that really brought about changes, in new construction first of all. Indeed, the construction of new residential areas often involved the installation of a district heating network, usually supplied by a power plant operating on oil or coal. To meet this demand, Chauffage Service transformed itself in 1960: it became the Compagnie Générale de Chauffe (CGC) and relied on its expertise to develop heating networks and energy performance activities through public service delegation contracts. Its motto was “Save fuel.”

Leon Dewailly, the Heating Engineer

Leon Dewailly was born in Lille in 1895. This engineer by training became a heating operator and founded his own company, Chauffage Service, which invented the principle of energy performance contracts. Starting in 1937, Leon Dewailly signed the first energy performance contract in history with the Villiers-Saint-Denis hospital. This heating contract, known as “P1, P2, P3,” covered energy supply, maintenance, and installation, as well as equipment renewal. Ensuring supply security and service continuity were at the core of this innovative company’s promise.

However, it was only ten years later, at the end of World War II in 1944, that the engineer founded the Compagnie Générale de Chauffe (CGC).

The company experienced rapid growth thanks to its multi-service contracts offered to the American bases of NATO, as well as to the booming collective housing and urban heating sector during the Trente Glorieuses.

Leon Dewailly also looked toward the international market and, in 1963, he established the Compagnie Générale de Chauffe Belge, followed by Associated Heat Services in Great Britain in 1966, launched through a partnership with the National Coal Board. The company took a decisive turn the following year when it sold 40 percent of its shares to Compagnie Générale des Eaux. Leon Dewailly retired from his position at the age of 86 in 1981. Ten years after his death in 1998, CGC became Dalkia, while still preserving the fundamentals inherited from its illustrious ancestor.

Diversification of Heating Sources Accelerated by Oil Crises

As early as the 1960s, the very first incinerators capable of supplying heat networks through waste combustion were built, foreshadowing their transformation into “energy recovery units” (ERUs) in the 1980s and 1990s. Technically, some incinerators had already been able to recover energy for a long time: in 1907, the Issy-les-Moulineaux plant produced electricity using a turbo-alternator, and the Tours incinerator, built by the Society of Enterprises for Industry and Agriculture (SEPIA) in the 1920s, produced both electricity and bricks made from the ashes. Inaugurated in 1968, the Villejean plant took things a step further by both producing electricity and heating a part of the Rennes metropolis—the first plant of its kind!

The Breton Heating Exploitation Company (SOBREC) was created in December 1964 to operate the urban heating network in North Rennes. It was a subsidiary of the Compagnie Générale de Chauffe, 40 percent of which was owned by the Compagnie Générale des Eaux from 1967 onwards. Expanding the range of services it can provide to an area, the Compagnie Générale des Eaux fully integrated CGC into its group in 1980. It had already developed its own energy activities; in Rhône-Alpes, enterprising teams had established ECHM (Eau et Chaleur de Haute-Montagne) in 1963 to meet the water and energy supply needs of emerging Alpine ski resorts.

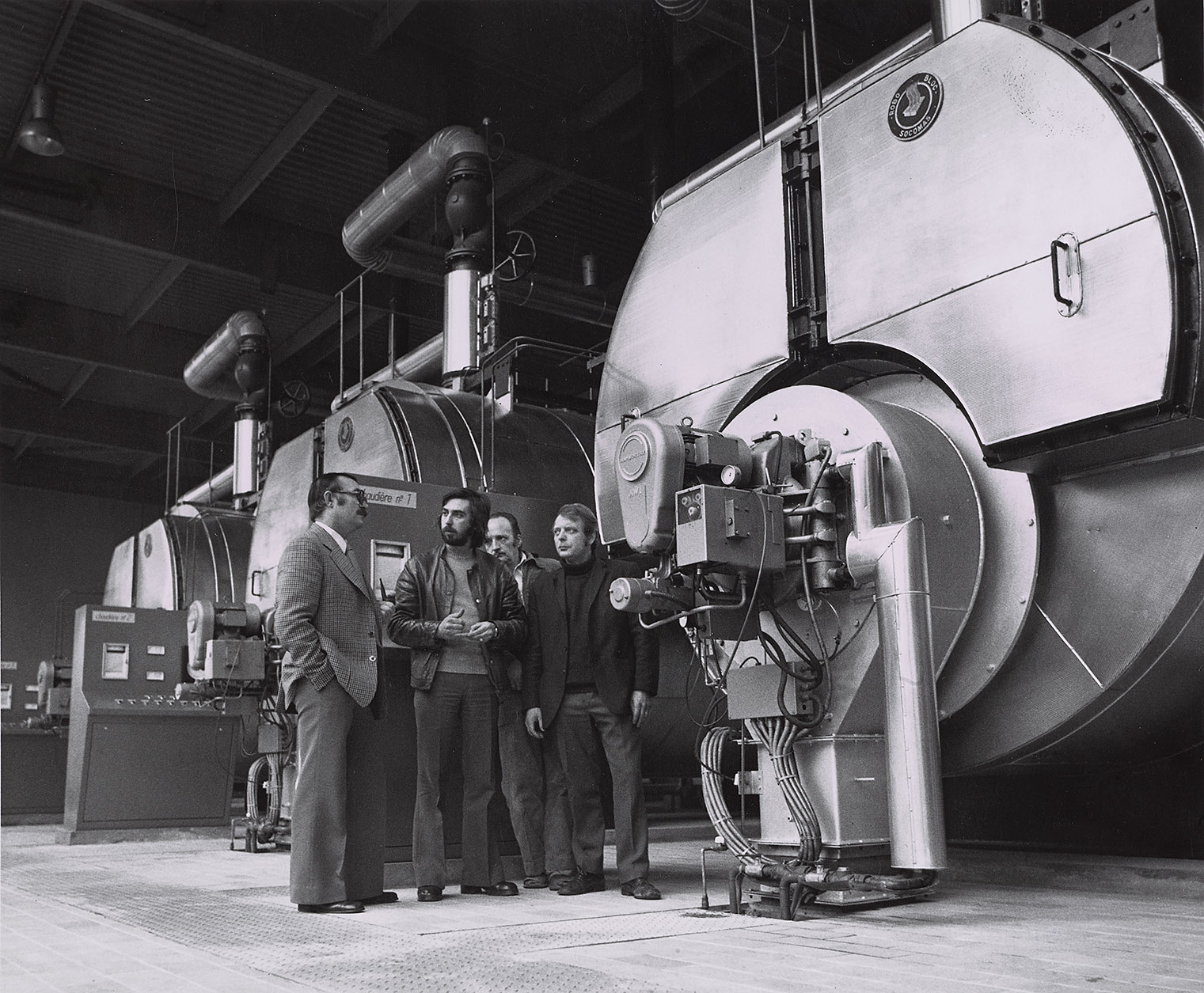

Indeed, “the skills required to maintain water and heat networks, even boiler rooms, were found to be similar, especially when considering the specifics of the mountain climate, from snow removal to coping with large temperature variations,” says Bruno Godfroy, Deputy General Manager of the Water France business unit. A few years later, in 1979, just before its full integration into CGE, Compagnie Générale de Chauffe produced a detailed report on its activities, demonstrating how the company had developed in response to energy crises caused by oil shocks. It had implemented various solutions such as geothermal heat, alternative fuels, heat from incinerators, heat pumps, and photovoltaic panels. CGC deployed these solutions throughout France and internationally, including in Belgium, Germany, Great Britain, Switzerland, the United States, and even hospitals in Saudi Arabia. It also considered developing energy from thermal power plant waste and photovoltaic panels, which were already being used to produce hot water for a holiday village in Martinique. Through a rudimentary remote monitoring system it had developed, precursor to the later Veolia Hubgrade centers, CGC's agents could remotely control temperature, consumption, and potential alarms across equipped networks in cities such as Rennes, Rungis, and Lille.

© Veolia Archives

The contracts signed in 1979 represented 46,300 kilowatts for heat production and 11,100 kilowatts for cooling, serving not only private individuals but also hospitals, the Post Office and Telecommunications administration, and hotel centers. As of the 1960s, CGC managed sixteen municipal waste treatment plants and in 1969 it installed its first geothermal system in the priority urbanization zone of the Almont department in Melun, which provided hot water for nearly three thousand residents. This was followed by installations at the Mont-de-Marsan air base, 826 housing units, a shopping center, a gendarmerie barracks, a nursery school, and a daycare center in Blagnac. During the 1980s, as a result of the oil crises, district heating networks gradually moved away from oil and turned massively toward natural gas or waste recovery energy.

In the 1980s and 1990s, incineration plants increasingly shifted their focus toward energy production. According to Patrick Hasbroucq, incineration activity used to be primarily about the destruction of waste, but since the 1980s, incineration has represented only a small part of the installations, alongside smoke treatment and energy production in the form of heat and/or electricity. Attention is now focused on the environmental and energy performance of the plants. However, there is still considerable room for improvement in this area.

Currently, only 62 percent of district heating networks in France are supplied by renewable and waste recovery energy. In 2021, a report from the Court of Auditors emphasized the importance of private operators in this activity and the benefits that individuals can derive from it. Due to the significant investments required to create a district heating network, the majority of public networks (80 percent) are operated through public service delegation. District heating and cooling networks supplied by more than 50 percent renewable energy allow users to benefit from a reduced VAT (5.5 percent) on the energy supply portion of their bills. These strong incentives encourage further development and greening of these networks.

Performance: A French and Italian Heritage

In 1998, the Compagnie Générale des Eaux was renamed Vivendi. It then created a subsidiary called Dalkia, which brought together companies specializing in energy services, including the Compagnie Générale de Chauffe and other companies acquired by CGE over the years. Esys-Montenay also joined the venture, itself resulting from the merger of Montenay, a company founded in 1860 that initially focused on traditional heating, district heating, fuel trading, and air conditioning, and Esys, a holding company created by Elf in 1986 that brought together former coal trading companies. As a European leader in energy and environmental efficiency, Dalkia signed an agreement with EDF in 2000, with EDF acquiring a 34 percent stake in Dalkia and enriching it with its own energy service subsidiaries. This partnership ended in 2014 when EDF retained the brand and French activities, while Veolia took over the international activities. It is within Dalkia that the culture of energy performance contracts would become even more important, following the historical path of the Compagnie Générale de Chauffe and an Italian company founded in Milan in 1927, which joined Dalkia in 2002: Siram (from the initialism for Società Italiana Riscaldamento Appalti Milano). Siram built its reputation on energy performance and supply security, managing boiler rooms for private individuals, businesses, and institutions for decades, as well as selling wood, coal, and oil. Its first historic contract was signed with the city of Venice in 1927, when the Compagnie Générale des Eaux—a long-standing association—operated the water service in Venice and supplied boats that transported wood and coal through the Venetian canals for boilers in schools, museums, and offices. Over the years, the company specialized in energy performance, building design, and maintenance of technical, thermal, and electrical systems.

© Veolia Archives

These strengths allowed Siram to secure the energy supply of crucial institutions such as the hospital in Parma, with which it has collaborated since 1951. As an example of its expertise, at that time, Siram managed only simple oil-fired boiler rooms in the hospital, but in the 1970s, it installed a large boiler, followed by a steam distribution plant in the 1980s. In the 2010s, it switched to natural gas, which is less polluting than oil, thanks to a type of underground thermal power plant known as “trigeneration.” This cutting-edge technology allows for the production of high-temperature thermal energy for hot water and heating, low-temperature thermal energy for air conditioning or refrigeration, and mechanical energy capable of generating electricity. Today, with its 1,137 beds, 31 operating rooms, and 3,700 employees, the hospital produces 47 percent of its electricity needs and 100 percent of its thermal needs. In addition to these achievements, the building's carbon footprint has been reduced by 3,825 tons of CO2 per year since the renovation work carried out by Siram.

In 2020, the Covid crisis highlighted the importance of securing the energy supply for strategic buildings such as hospitals. In Italy, in the hardest-hit regions, the Veolia group faced this emergency by ensuring the continuity of essential services at all costs while protecting its staff from risks. More than half of Siram Veolia's three thousand employees were deployed in Bergamo, Genoa, Parma, Bari, and Venice to operate seven hundred healthcare facilities, including over forty thousand hospital beds, and to urgently supply improvised intensive care units. During these challenging months, the staff secured essential services for the hospitals, including the management and maintenance of technological systems for energy production and distribution, air treatment systems, water quality control, and disposal of special hospital waste.

Veolia's smart monitoring tool, called Hubgrade, proved particularly valuable during this period, allowing agents to remotely monitor the installations continuously. According to Francisco Silvério Marques, Director of Building Energy Services at Veolia, Hubgrade was developed to improve the energy performance of sites by using digital analysis capabilities to enhance the impact of the actions carried out by the teams operating the facilities. This dual local and remote involvement is part of the group's DNA and also helps address the primary goal of securing energy supply.

In Central and Eastern Europe, Expertise Developed to Meet the Challenge of Energy Sovereignty

Let's head east, about eight hundred kilometers from Italy, to Central and Eastern Europe. Since the fall of the Berlin Wall, the former countries of the Eastern Bloc have gradually embraced market economies. Today, these countries, known as Central and Eastern European countries (CEECs), including Bulgaria, Croatia, Estonia, Hungary, Latvia, Lithuania, Poland, Romania, Slovenia, Slovakia, and the Czech Republic, have had to undergo profound changes in their understanding of public services. Over the course of the 1990s, the population had to adjust to the fact that previously free services now had to be paid for in order to increase their efficiency and reliability.

One of these services was energy supply. At the end of the twentieth century, the young democracies of Eastern Europe faced another colossal challenge: how to ensure energy sovereignty when almost everything had to be built from scratch? While strategies and public policies varied, one constant emerged: each state relied on local or foreign companies to lay the foundations for this desired independence and to apply for integration into the European Union.

During this period, Veolia accompanied these countries in reducing their dependence on Russian coal and gas and contributed to their improved energy autonomy. In 2022, the group supplied energy to twelve million inhabitants in the region. Veolia has gained the trust of many countries thanks to its industrial legitimacy as an energy producer and distributor. But it's not just about that. “We provide solutions that are sustainable. Our values are society, hygiene, safety, and transparency,” says Philippe Guitard, Director of Central and Eastern Europe at Veolia. This trustworthiness has paid off; for example, Veolia's revenue in the Czech Republic reached 1.5 billion euros in 2022, even though the company had not yet established itself in the country in 1997.

in Hungary produces heat and energy from wood and straw.

© Veolia Media Library - Stéphane Lavoué

Urban district heating networks are the primary activity through which Veolia has established a long-term presence in the CEECs. In cities such as Warsaw, Poznan, and Lodz in Poland, Bratislava in Slovakia, Budapest and Pecs in Hungary, and Prague and Ostrava in the Czech Republic, Veolia operates and modernizes thermal power plants. “In these countries, about 90 percent of medium and large cities are heated by collective district heating networks due to harsh winters. The current challenges are to secure heat supply and reduce the carbon footprint of the power plants,” says Renaud Capris, CEO of Enova, former Director of Operations in the Czech Republic, Bulgaria, and Hungary.

Over time, the environmental performance of heat production units has been improved, as the standards of the 1990s were not strict enough. The CEECs’ accession to the European Union in the early 2000s forced them to adopt the same rules as Western European countries, which required significant renovation work. “There is a proactive desire to gradually phase out coal-fired power plants. The city of Pecs in Hungary, with a population of about 200,000 inhabitants, has successfully converted its entire district heating network to biomass, completely eliminating coal and gas. Straw is collected from local farmers, as are wood residues,” explains Renaud Capris. Most CEECs are in the process of transitioning to cleaner solutions such as biogas and biomass in order to move away from coal. “The goal is to offer alternatives at a reasonable cost for consumers,” Renaud Capris adds.

Veolia has been present in this region of the world for over twenty years, where energy issues play a crucial role in political and economic balances. This has become even more true since the beginning of the war in Ukraine in February 2022. One of the consequences of the Russian invasion is an increased awareness among the public of the significant dependence on Russia for energy supply, especially gas. Energy autonomy is no longer just an ambitious goal; it is now a regional security issue. The secure access to local energy has been at the heart of European regulatory developments since then, aiming to produce and distribute energy through the most efficient means to preserve resources. As a partner to local communities, Veolia designs and develops tailored solutions, allowing its clients to gradually overcome the uncertainties associated with market price fluctuations.

The story of energy intertwines with the turbulent history of a region at the center of important geostrategic issues. “Although reserves of oil, gas, and nuclear fuel remain, their sharp decline and the search for alternatives have led to a paradigm shift: the deployment of low-carbon technologies and energy efficiency are now matters of national and economic security,” writes researcher Diana-Paula Gherasim on the website of the French Institute of International Relations (Ifri). She adds, “The risk of a carbon wall being erected in Europe between the West and the Central and Eastern European Member States is no longer relevant.”

Energy sovereignty, decarbonization, and purchasing power converge fundamentally. While Central Europe still remains dependent on coal, there are numerous plausible opportunities to modify the energy mix. “Renewable energies are the cheapest source of electricity production for Poland, the Czech Republic, Romania, and Bulgaria"4, highlights a 2020 report by the Bloomberg NEF expert group. According to the authors of the study, a massive energy transition in the region would reduce CO2 emissions from the electricity sector by 50 percent in ten years, making a 6 percent contribution to the European Union's emissions reduction targets.

For Francisco Silvério Marques, the future lies in energy savings and accelerated decarbonization. “In ten years, we will no longer be able to have energy service contracts based on fossil fuels. We will need to use on-site, decarbonized energy, local and renewable, which reduces environmental impact, promotes autonomy, and improves price visibility. Today, we are proficient in downstream operations, optimizing energy use, and we will continue to progress by guaranteeing even more energy savings. At the same time, we must continue to strengthen our upstream activities: our capacity to produce local and renewable energy to meet the needs of our clients.” This vision of a decarbonized future could well materialize throughout the entire Old World and beyond.

- Braudel, Fernand, L’Identité de la France : espace et histoire [The Identity of France: History and Environment, London: Collins, 1988], Paris: Flammarion, 2009 (Arthaud Flammarion, 1986). ↩︎

- Williot, Jean-Pierre, “Du déclin au renouveau : l’énergie gazière en France au xxe siècle [From Decline to Renewal: Gas Energy in France in the Twentieth Century],” in Les Annales des Mines, August 1998. ↩︎

- Collective heating is the centralized production of heat for an entire building, as opposed to heating systems that are individualized for each apartment, or to electric radiators. Urban heating is the production and distribution of heat for an entire village or at least a neighborhood. ↩︎

- Bloomberg NEF (2020). « Investing in the Recovery and Transition of Europe’s Coal Regions ». ↩︎