Decarbonizing Energy: Local Solutions for a Global Problem

The terms used in the energy debate are often misleading. They are, in fact, produced by the actors themselves in a sector that is both highly material, marked by constraints and inertia, and highly speculative, involving visions of the future. As historian Jean-Baptiste Fressoz has shown, the notion of energy transition, popularized in the 1970s, masks the way in which a new energy source is added to existing ones instead of replacing them. This is the real challenge for renewable energy: is it once again about providing an additional energy supply through the use of a new source alongside existing ones or about reducing the extraction of fossil fuels? The victory of coal over wood in the 1860s relied—long before energy efficiency, which came much later—on a conceptual tour de force invented by English economists: defining materials manufactured by natural processes that have taken millions of years as “stocks,” a kind of underground department store to be discovered. Rather than using the term “renewable,” which could establish an eco-modernism reactivating the ideal of limitless energy, the future tour de force would be to consider all energy to be limited, which is the case for the total quantity of energy on Earth, and thus to prioritize circularity over addition.

Grégory Quenet

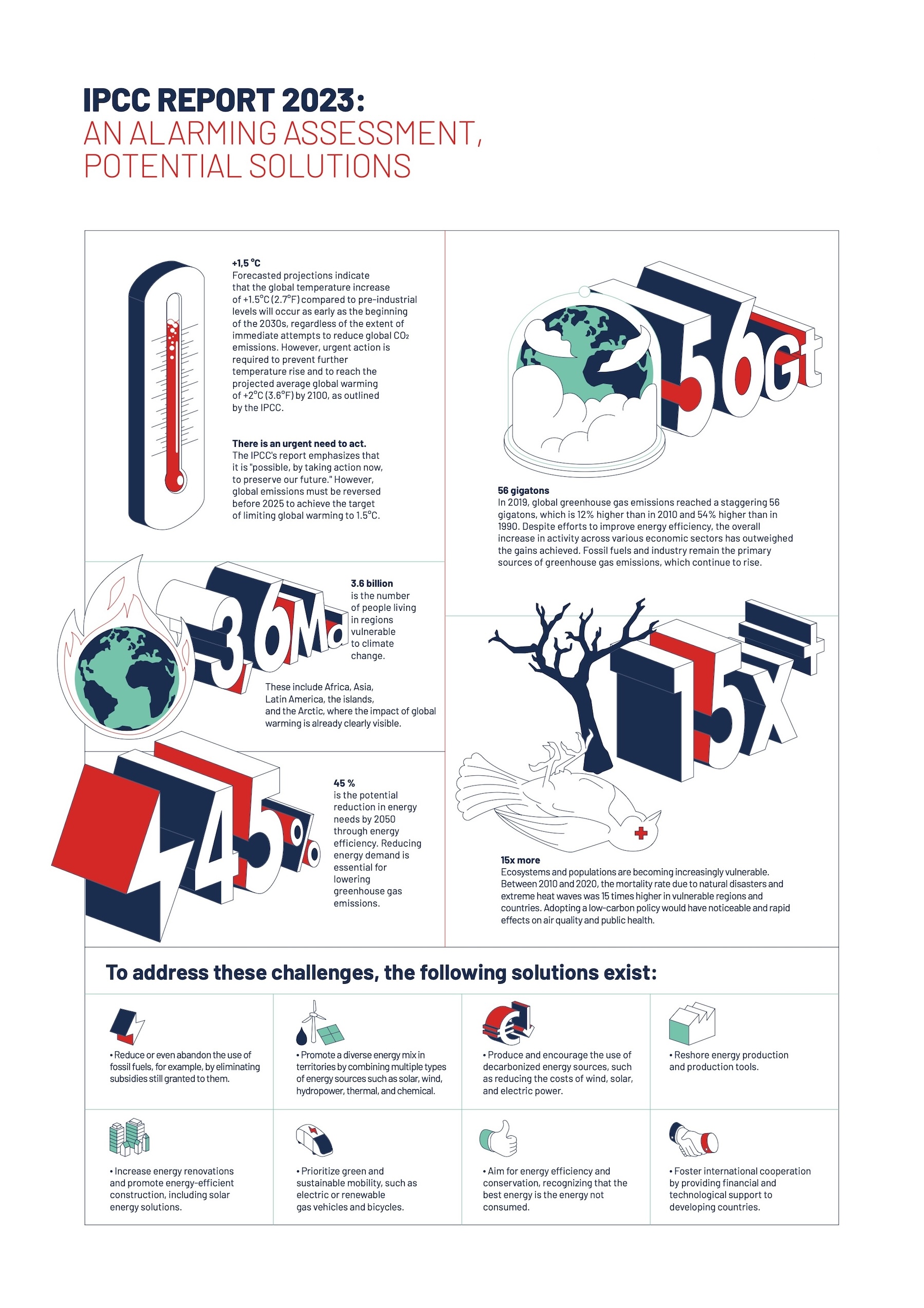

The sixth report by the Intergovernmental Panel on Climate Change (IPCC), released in March 2023, confirms that the Earth's temperature continues to rise, reaching its highest level in the past 125,000 years during the 2011–2020 decade. Scientific experts estimate that by 2030, the planet will have warmed by 1.5°C compared to pre-industrial times, regardless of immediate efforts to reduce global CO₂ emissions. We are already living in the era of climate change and its consequences.

In order to preserve the future of life on Earth, the IPCC outlines a path to cap emissions growth in the short term and reduce emissions in the long term, with the goal of achieving carbon neutrality by 2050. Energy, whose consumption has been exponential since 1850, has a crucial role to play. While it is predominantly fossil-based today and releases billions of tons of carbon that had been sequestered over millions of years on Earth, the group of scientists estimates that up to 77 percent of global energy needs could be met by biomass, solar, wind, hydroelectricity, geothermal, and marine energy, alongside the necessary energy savings. This massive shift to clean energy sources represents the greatest potential for short-term reduction in greenhouse gas emissions by 2030. Modifying the energy system is possible: the declining costs of renewable energies and green technologies observed in recent years, from solar to wind, can facilitate the energy transition, much like the shift from wood to coal accelerated the system’s use in the mid-nineteenth century. However, unlike what happened then, this is still subject to strong political will, especially given the urgency of the situation.

The decarbonization of the energy mix has indeed begun to permeate public policies. The European Union goes so far as to make it an element of leadership: the Council of the European Union launched a step-by-step adoption process in 2021 for the so-called “Fit for 55” package, which includes thirteen legislative proposals defining the objective of reducing net greenhouse gas emissions by at least 55 percent by 2030 compared to 1990. Among these proposals, the promotion of renewable energies is central, also on the agenda of the REPowerEU plan in 2022, alongside the strengthening of natural carbon sinks, the end of sales of internal combustion engine cars by 2035, the reduction of energy bills for buildings, and the overhaul of energy taxation.

On the ground, things are changing. Germany is one of the first countries to have clearly shifted its energy policy: while renewable energies represented 6.89 percent of electricity production in 2000, they now provide 49 percent of German electricity in 2022. Other countries such as the United Kingdom, the United States, and China have caught up in a matter of years. By introducing a carbon tax in 2013 and launching low-carbon electricity production support programs in 2014, England has succeeded in making renewable energy the country's primary source of electricity in 2020. For the first time in the first five months of 2023, solar and wind power in the United States have surpassed coal in electricity production. Thanks to subsidies, but also to more flexible legislation in certain states, states such as Texas, a solar energy champion, and California, which aims for 100 percent renewable electricity by 2045, stand out. In China, the capacity for wind and solar energy production has increased tenfold since 2010, and the country holds a large share of industrial production of photovoltaic panels (63 percent of cells, for example) and wind turbines (over 40 percent).

Even in France, the situation is changing. Because “France has not been a promoter of renewable energy, it is lagging behind compared to all European countries,” says Jacques Vernier, director of the Agency for Ecological Transition (Ademe) from 1994 to 1997. The prevalence of nuclear power has reduced our fossil energy consumption, but it has also slowed down renewable energy development, and France is still behind on its objectives. However, the development is nevertheless exponential: “In 1996, when I wrote the Que-sais je? book, I noted that there were only three wind turbines in France, in the Aude region,” remembers Jacques Vernier. “In 2023, there were 8,000.” However, the global equation is not yet solved: fossil energy consumption continues to increase. According to the International Energy Agency, global natural gas demand could increase by 28 percent and oil demand by 17 percent by 2050.

That is why many experts, like historian Jean-Baptiste Fressoz, reject the term “energy transition” in favor of “energy stacking,” with each new energy source being added to the mix of each country throughout history. How can we avoid this scenario and fundamentally reverse the trend? Some regions are beginning to outline an “energy unstacking,” similar to what is happening in Europe and even North America, which is reaching a plateau. With the solutions it has developed and the innovations it is working on, the Veolia group can amplify this movement. This is the objective that Estelle Brachlianoff placed at the heart of the ReSource plan in 2022: to reduce energy consumption and increase the group's green energy production.

Using Recovery Energies to Move Away from Fossil Fuels at the Local Level

Veolia has developed solutions to enable territories and industries to move away from coal and other highly carbon-intensive energies, at the intersection of two long-standing expertise areas: energy recovery from waste and the operation of district heating networks, which connect production sources to consumption sites.

As early as the late 1960s, the Compagnie Générale de Chauffe (CGC) operated an incineration plant supplying heating to certain neighborhoods in the city of Rennes. Since the 1980s and in response to the oil shocks, new French incineration plants—now called “energy recovery units” or ERUs—have been equipped to recover heat from waste, while older plants have gradually been updated. The proximity of the ArcelorMittal plant near Nantes even contributed to the location of the Arc-en-Ciel waste recovery plant in Couëron, operated by Veolia since 1993.

The group's expansion into Eastern Europe in the early 2000s has accelerated the development of its expertise in the operation of district heating networks and their greening. One of the first examples is the district heating network in the city of Pécs, Hungary, established in 2005: the homes of the city's 200,000 inhabitants are now almost entirely heated through the urban network, which no longer uses coal or gas, both of which are major CO₂ emitters, but only biogas. Some of this biogas is obtained from straw collected by local farmers and from recovered wood residues. Combined heat and power generation techniques, and even trigeneration—the production of electricity, heat, and cooling from the same source—have since proliferated everywhere.

This combined expertise is now contributing to the decarbonization of cities where it can be replicated. This is the case for the European metropolis of Lille, where, thanks to the recovery of waste as electricity and heat, the last coal-fired power plant in northern France was closed in 2021, thirty years after the closure of the last mine in the region. “In France, there is no other network equivalent to the one in Lille,” explains Patrick Hasbroucq, director of industrial units at Veolia. “It is even the longest in Europe, with a twenty-kilometer connection between the plant and the city.” In terms of energy, the plant ensures the recovery of all municipal waste in the Lille metropolis, delivering 270 gigawatt-hours of heat per year, equivalent to the consumption of thirty-five thousand homes, and 91 gigawatt-hours of electricity, sufficient to meet the demand of twenty thousand households. Economically, the project has demonstrated its viability: the forty-million-euro investment by the metropolis will be offset over time by energy revenues, and for subscribers, the energy price is particularly competitive due to a reduced VAT rate of 5.5 percent on the variable portion of the bill.

Most importantly, this new infrastructure is also beneficial for the environment: coal dust emissions have been significantly reduced, and fifty thousand tons of CO₂ are avoided each year, equivalent to fifty million round trips between Paris and Lille by high-speed train. It also contributes to the decarbonization of industries, such as in Lorraine, where Solvay has been producing soda ash, an industrial by-product with multiple uses, from the manufacture of glass to toothpaste for over a hundred years. The chemical manufacturer has partnered with Veolia to replace three coal-fired boilers with a boiler equipped with two furnaces that operate on solid recovered fuels (SRF), waste that cannot be recycled. As carbon quotas are gradually applied to European industry, this will support the site's competitiveness and maintain employment by reducing the carbon footprint of industrial activity by half and eliminating the annual importation of 200,000 tons of coal.

The development of district heating and cooling networks today aims to maximize the use of every bit of energy by sharing energy from decentralized production locations. In 2023, Veolia was entrusted with the operation of the Paris-Saclay network, a unique installation in Europe combining deep geothermal energy and the recovery of waste heat from the CNRS supercomputer and the cooling network. The system aims to double the delivery of heat and cooling to support the urban campus's real estate development.

Recovered energy is at the heart of a paradigm shift with immense potential both from an ecological and energy sovereignty perspective. “In the past, we operated in a mode where we produced energy when we needed it,” says Gad Pinto, director of local energy loop activities at Veolia. “However, when we produce energy in this way, a lot of energy is wasted. For a long time, this didn't bother anyone: why bother recovering it when the primary energy source is virtually free? Today, that is no longer the case: we seek to recover heat from data centers, wastewater, industrial processes in the steel, chemical, cement, and agri-food sectors, etc. Furthermore, when relying on the national gas or electricity grid, if it is cut off from certain supplies such as Russian gas, a company or community finds itself in a vulnerable situation. The development of local solutions helps address this.”

Scaling up to all territories requires the capacity to integrate different expertise, which is gradually happening, as measured by Annaïg Pesret-Bougaran, director of the Arc-en-Ciel plant: “In 1993, our plant was a completely innovative project, to the point that three subsidiaries of the group formed a partnership to respond to the call for tenders, with each bringing their expertise in incineration, waste sorting, and district heating. Today, everything is more integrated thanks to our experience.” The novel technology is gradually being industrialized to have a greater impact.

Maximizing Impact by Mobilizing All Resources

By energetically recovering non-recyclable waste from incineration plants or landfill sites, Veolia ensures the best possible use of the resources entrusted to it. The same logic is applied by the group in the valorization of wastewater and the sludge extracted from it, in installations that cover tightly-knit territories. Wastewater treatment plants are thus the preferred sites for the deployment of anaerobic digestion, which transforms organic matter into energy. “The two historical sectors that have developed anaerobic digestion,” explains Julien Thual, anaerobic digestion engineer for Ademe, “are the agri-food industry and urban wastewater treatment plants, for the purpose of treating their sludge and recovering biogas as heat. These activities were carried out in cogeneration, producing electricity and recovered heat, which were valorized around the anaerobic digestion plant.”

Indeed, wastewater treatment plants produce large quantities of sludge during their treatment process, which can be reduced in volume and organic load. How? By transforming them into energy. According to Alain Le Divenach, head of Structuring Projects for the Mediterranean region at Veolia, “a hundred years ago, the group's first drinking water plants in Nice and Toulon were already producing their own electricity using a turbine. Since the electricity grid was less developed than today, our predecessors had the motive to produce a part of their energy with water. And then it was abandoned for economic reasons. Digestion (the process that allows for a significant reduction in the volume of sludge produced), the stabilization, and the generation of biogas were also used in the past, and for a while, we switched to very large basins with very long stabilization times, which are energy-intensive.

In recent years, we have renewed our interest in digestion, which is making a comeback in our plants. We are also interested in significant pressure variations between reservoirs. Generally, to avoid a sudden influx of water with a high jet, pressure reducers are installed. Increasingly, we are replacing the reducer with a turbine: with it, there is no mechanical dispersion, and we produce electricity.”

When Water Waste Becomes Energy: Sewage Sludge

Sewage sludge is the main waste produced by a wastewater treatment plant from the various liquid effluents it processes. It consists of organic and mineral matter and can be categorized into three types.

Primary sludge, which results from the settling of effluents and has a high mineral content; physico-chemical sludge, which is similar to primary sludge but contains flocculating agents; and biological sludge or activated sludge, which is produced through bacterial treatment.

“With the boom in wastewater treatment plants, the volume of sludge has significantly increased,” says Paul-Antoine Sebbe, CEO of SEDE, a Veolia subsidiary specializing in sludge treatment and valorization. Similar to wastewater, the major challenge therefore is to no longer consider sludge as waste, but as a resource to be valorized. So what can be done with this sludge?

Pierre Forgereau, Director of the Artois Douaisis region at Veolia, explains the three main ways to valorize industrial and urban sludge. Firstly, while ensuring sanitary quality, “these sludges can be used for agricultural land spreading. This has an agronomic impact, as they increase the fertilizing value of the soil,” he explains. Currently, 75 percent of sewage sludge is spread on agricultural land.

Sludge can also be composted with other green waste to create agricultural inputs and provide fields with richer organic matter.

“The third valorization option is to convert it into biogas. This is something that has existed for a long time but is now being revisited due to the energy crisis. More and more municipalities, such as those in Angers or Hénin-Beaumont, are investing in biogas production,” highlights Forgereau.

Today, energy production ensures the continuous operation of facilities and supplies the surrounding areas in need. Philippe Guitard, director of the Central and Eastern Europe zone at Veolia, explains their expertise in energy recovery through a digester that processes various waste materials, such as expired yogurt, to generate green electricity that can be sold to cities like Bucharest or Budapest. In Sofia, Bulgaria, Veolia manages the first positive energy wastewater treatment plant in Europe, which has produced 23 percent more energy than it consumes and sells the surplus electricity to the public grid operator.

In Braunschweig, Germany, Veolia has made the wastewater treatment plant self-sufficient. Similarly, in Cagnes-sur-Mer, France, the first positive energy wastewater treatment plant was launched in 2021. By valorizing the available heat and energy at each stage, this French plant produces 10.5 gigawatt-hours of biomethane per year, exceeding its consumption of 8.7 gigawatt-hours and injecting the surplus biomethane into the GRDF network. In Fréjus, the valorization of sludge from the wastewater treatment plant also provides green fuel for public transport, with the biomethane produced equivalent to the consumption of over 40 percent of the city’s public bus transport network. Julien Thual, from Ademe, concludes that methanization is one of the most virtuous forms of energy, as it offers multiple benefits, including the substitution of mineral fertilizers with organic fertilizers, continuous energy production throughout the year, and local resilience.

Solar energy also plays a role in Veolia's decarbonization efforts. Particularly in seawater desalination activities, where Veolia is a global leader, solar energy is being utilized to reduce the environmental impact. Advanced reverse osmosis technologies have already reduced the energy required for seawater desalination by approximately 80 percent since the 1980s. Now, with the industrial deployment of solar energy, Veolia aims to go even further. Renaud Capris, director of Enova, explains the shift from high carbon footprint desalination solutions to a mix of solar and electrical energy, with future plans to use only solar and hydrogen to power the plants. For example, the Sharqiyah Desalination plant in Sur, Oman, has installed thirty-two thousand high-efficiency solar panels equipped with an east-west tracking system to optimize energy production based on the sun's orientation. This installation will generate over thirty gigawatt-hours of green electricity per year, meeting more than one-third of the daily consumption of the desalination plant, which provides water to 600,000 people.

On the other hand, Veolia is utilizing smaller areas of land for solar energy production, especially in post-exploitation waste storage sites. For instance, on the former Tougas landfill near Nantes, Veolia installed photovoltaic panels on ten hectares of land in 2019. These panels produce eight gigawatt-hours of electricity per year, supplying power to over a thousand households. Veolia aims to make its services energy self-sufficient throughout France by combining various solutions such as waste valorization, methanization, biofuel production, and photovoltaic energy development on its sites. Jean-Christophe Taret, director of ecological transformation for the France and special waste Europe zones at Veolia, emphasizes the importance of resource valorization in decarbonizing the group’s activities and highlights the need for both extensive and intensive approaches. Extensive approaches involve generalizing techniques across all installations, such as biogas capture worldwide. Intensive approaches focus on isolating and maximizing the value of each resource stream, such as specifically collecting biowaste in France.

Supporting the Transition of Energy Sources and Making Green Energy Greener

Veolia's mission for the coming years is not only to optimize the value of each resource stream but also to support the transition to renewable energies and make green energies even more circular and resource-efficient.

Nuclear Energy, a Transition Energy to Be Secured

In France, Japan, and the United States, Veolia Nuclear Solutions (VNS) is involved in activities related to hazardous waste treatment and decontamination applied to nuclear energy. Jean-François Nogrette, director of the France and special waste Europe area, explains the origins of this subsidiary, step by step, as the group assumes the practice: “In France, the Atomic Energy Commission (CEA) uses a cold solidification technique called vitrification for radioactive waste, which was initially licensed by Veolia, created from its hazardous waste activity.

Following this experience, we took our first steps in the nuclear sector before deciding to pool resources to establish a specialized activity and reduce costs. Since then, we have acquired a business in the dismantling and treatment of radioactive waste, and we have opened a radioactive waste treatment facility in Texas with a treatment process that follows the same logic as that of hazardous waste, in which we are one of the world leaders with SARP Industries.” With technologies such as Geomelt, which allows the vitrification previously reserved for highly radioactive waste to be applied to low-level radioactive waste, Veolia now enables the reduction of nuclear waste volumes in collaboration with partners like EDF, addressing the core issue of the acceptability of this energy source.

The tsunami that struck the Fukushima nuclear power plant in Japan in 2011 was another opportunity for Veolia's teams to demonstrate their nuclear expertise, combining short-term and long-term solutions. Immediately after the disaster, the company's engineers developed a water cooling system (ISMS) capable of safely treating the cesium-contaminated water in the plant, cesium being a highly radioactive element. Over the following decade, Veolia developed new technologies, particularly in robotics, for the dismantling of the site. Remotely operated robots capable of inspecting and repairing the damaged containment vessel and working in the extremely hot and radioactive reactor core were developed. The Boom robot, for instance, was designed to unfold an arm composed of different segments in an extreme environment. Dominique Richit, former CEO of VNS, explains: “Radiation burns chips in record time, so we opted for remote electronic control in a protective casing. The arm itself contains very few electronics. Measurements are transmitted by electrical signals from the robot's end to the control room. »1

Optimizing the lifecycle of each energy source

In addition to securing nuclear energy production and optimizing its environmental impact to ensure greater acceptability, Veolia adapts to the choices made by local or national communities to apply the same logic to each type of energy adopted. In Japan, for example, after the Fukushima nuclear disaster, the country shifted its energy strategy towards renewable energies, aiming to reduce nuclear energy from over 30 percent to less than 20 percent.

© Veolia Media Library - Shin Takahashi

In line with this diversification strategy, Veolia collaborates with local industrial player Takeei to rehabilitate forest resources for biomass electricity production in Japan. Veolia currently manages several biomass plants in Japan, ensuring the highest level of energy efficiency from this resource.

Wind energy, a widely promoted renewable energy source worldwide, must demonstrate its positive impact to gain support from the public. The recycling of wind turbine blades is one key issue that needs to be addressed. While the carbon footprint of wind turbines is good, their blades, made mostly of composite materials such as fiberglass, are difficult to recycle. Many first-generation wind turbines are reaching the end of their lifespan (which averages twenty years), and the University of Cambridge estimates that there will be forty-three million tons of used blades by 2050. Without proper treatment, these blades could end up in landfills.

Veolia is working on finding ways to give these blades a second life by using them in cement production. In 2020, the company reached a milestone with GE Renewable Energy. The goal was to recycle these blades during the revamping or repowering of GE's onshore wind farms in the United States. The recycling process begins on-site at wind farms, where the blades are removed and transported to a facility where powerful machines shred them into smaller pieces. These pieces are then transported to a Veolia plant, where they undergo further grinding to reach the size of gravel. Through this process, over 90 percent of the blade's weight is valorized: 65 percent as a raw material, replacing sand, clay, and other materials, and 28 percent as an alternative fuel, replacing coal to provide energy for the chemical reaction in cement kilns. This unique contract in the American wind industry aims to valorize thousands of wind turbine blades in the coming years.

The electrification of energy production also highlights the importance of battery recycling. Battery production is highly carbon-intensive, and the rare metals they contain are at the center of sovereignty concerns. By 2035, when the ban on the sale of combustion engine vehicles will have just come into effect in the European Union, around seven million tons of batteries will be eligible for recycling. Veolia, with its historical expertise in battery and accumulator treatment, will mobilize its unparalleled knowledge across all stages of the recycling process. The solution involves five stages, including collection, secure storage, deep disposal, and refining of metals for reuse in new batteries. The recycling plant in Dieuze, France, dedicated to battery recycling, has significant development potential.

Toward Carbon Capture and Recycling

The capture, storage, and recycling of carbon are crucial mitigation options, even with maximum energy savings and a rapid transition to a greener energy mix. The Intergovernmental Panel on Climate Change (IPCC) affirms the essential role of these processes, particularly in the chemical and cement production sectors, stating that they are necessary to achieve carbon neutrality goals—especially those aiming to limit global warming to 2°C by 2100. Veolia is exploring the application of carbon capture solutions in its waste recovery facilities, especially as carbon capture is becoming economically viable. Just five to seven years ago, there was a significant gap between the cost of carbon and the cost of capture, making it economically unfeasible to capture and store carbon. However, things are changing, with the price of carbon per ton increasing from 37.45 euros in February 2021 to nearly 90 euros in March 2023. Additionally, some countries, such as the UK and the US, are implementing mechanisms to incentivize the development of carbon capture infrastructure, whose costs are decreasing with economies of scale and the development of new technologies.

While any currently captured CO₂ is primarily intended for sequestration in underground geological reservoirs, Veolia aims to go further and valorize it. Isolated CO₂ molecules can be used in various industrial applications, such as concrete and cement production, carbonated beverages, and low-carbon fuels. Veolia has partnered with the Collège de France, the French Alternative Energies and Atomic Energy Commission (CEA), and the Inter-municipal Sanitation Syndicate of the Paris Agglomeration (SIAAP) for research and development projects to transform CO₂ emitted by wastewater treatment plants into useful products.

The goal is to modify the molecular bonds through CO₂ chemistry to produce formic acid, used by the perfume industry, and methanol, a versatile solvent used in the production of varnishes and paints, in addition to biogas from wastewater. This alliance between fundamental, technological, and industrial research demonstrates the experimental stage of these efforts.

Overall, the solutions outlined here illustrate once again that the international climate and energy crises, which require a transformation of our production systems and habits, are resolved at the local level by replicating solutions developed worldwide. Veolia's ability to adapt and replicate solutions has made it a global champion in ecological transformation, a position that has been built patiently over decades since 1853.

In Braunschweig, Biomass Replaces Coal

Germany has historically been a major consumer of coal, and this fuel has played a crucial role in its energy sector for many years. Coal has been used for electricity production as well as for industrial needs.

However, over the past few decades, the country has gradually embarked on an energy transition, known as the Energiewende, aiming to reduce its dependence on fossil fuels, including coal, and increase the share of renewable energy sources in its energy mix.

And it is in Braunschweig that the new energy story of the country is being written. This city in Lower Saxony is home to BS|ENERGY, a subsidiary of Veolia. As the concessionaire for the city's electricity and gas networks, it is committed to being at the forefront of energy supply by offering flexible, environmentally friendly, and affordable solutions.

Its objective is clear: to support Braunschweig in its transition toward a future that is less dependent on carbon-based energy sources.

But how to replace coal? Among the preferred sustainable energy sources, biomass occupies a prominent place. The coal-fired heat and power production plant has therefore been replaced by a biomass cogeneration plant, fueled by wood waste from the region.

Commissioned in 2022, it has an electrical capacity of twenty-two megawatts and a thermal capacity of sixty megawatts, meeting the heat demand of nearly fifty thousand households. It helps to avoid the emission of eight thousand tons of CO₂ each year solely due to the abandonment of fossil fuels, as well as a reduction in harmful particulate emissions. Furthermore, the wood ash itself is transformed into fertilizer. This initiative offers a glimpse of a more environmentally friendly, greener, more sustainable future, focused on renewable energy sources.

In Finland, the Emergence of Carbon-Neutral Biofuel Production During the Paper Pulp Manufacturing Process

In 2022, Veolia launched the world's largest bio-refinery project in Äänekoski, Finland, producing carbon-neutral biomethanol from a paper pulp production plant.

Developed in close collaboration with Metsä Fibre, the largest forest cooperative association in Europe, the refinery relies on an innovative concept by Veolia to produce industrial-grade biomethanol from bioproducts on an industrial scale. This concept safely integrates a refining process of crude sulfated methanol into the paper pulp production process.

This industrial concept contributes to the energy security and independence of Europe, while supporting the European decarbonization ambitions of the Green Deal for transportation. Industrial-grade biomethanol, which is carbon-neutral, presents a new sustainable fuel source to replace fossil fuels.

With an annual production capacity of twelve thousand tons and expected commissioning in 2024, the plant will enable a reduction in CO₂ emissions of up to thirty thousand tons per year.

This bio-refinery project fully exemplifies Veolia's commitment to developing local energy loops and integrating solutions in various industrial sectors to locally produce carbon-neutral fuels.

Moreover, this industrial solution reveals the potential for an alternative source of raw material, estimated at around two million tons, for biofuel production. This concept, largely unexplored until now, can be replicated in nearly 80 percent of paper pulp plants worldwide.

In Portugal, a Prospective Study to Transform CO₂ from Waste into Aviation Fuel

“In 2018, commercial aviation accounted for 2.6 percent of global greenhouse gas emissions and 5.1 percent of anthropogenic climate warming between 2000 and 2018 when the effects beyond CO₂ are included, according to Carbone 4, the leading French consultancy on energy and climate issues. The combustion of fuel alone corresponds to approximately one billion tons of CO₂ per year, roughly equivalent to the emissions of Japan—the third world power and fifth largest emitter.”

Aviation is therefore facing an immense decarbonization challenge, which cannot ignore the question of its fuel. That is why, in 2022, a feasibility study was launched to establish one of the first synthetic e-fuel production units in Europe within the energy recovery unit (UVE) of LIPOR, near Porto, operated by Veolia.

The project would enable the industrial-scale production of alternative aviation fuels (SAF) from CO₂ captured in the residual gas stream of the UVE, combined with green hydrogen.

In the initial phase, up to 100,000 tons of captured biogenic CO₂ would be recycled to be converted into e-fuels and transformed into green synthetic end products such as e-kerosene, e-diesel, and other chemicals.

Technically, this CO₂ valorization project in the LIPOR UVE involves capturing, extracting, and purifying the biogenic part of CO₂, which constitutes approximately 60 percent of the carbon dioxide emissions generated following the incineration process.

According to the president of LIPOR, José Manuel Ribeiro, this project could “help Portugal position itself among the first countries to invest in the circular carbon economy,” while, as highlighted by José Melo Bandeira, CEO of Veolia Portugal, “the capture, storage, or use of greenhouse gasses are essential” to achieve carbon neutrality goals. While not a miraculous solution capable of resolving the competition between different energy uses, this project could contribute to addressing the climate challenge.

Adèle Peugeot

Employed at Veolia since 2022

Adèle Peugeot is a development and innovation project manager. A graduate of the École Normale Supérieure, with an MBA and a doctorate from the Collège de France, Adèle Peugeot believes in the collaboration between the research and industrial worlds, as well as in the importance of local action in addressing tomorrow's challenges. At Veolia France & Déchets Spéciaux Europe, she utilizes chemistry to serve sustainable development, particularly in decarbonization.

How can technology address the environmental challenges we face?

“If we want to collectively meet the challenge of a carbon-neutral world, we must leverage the complementarity between the research, innovation, and industrial sectors. While many solutions already exist, others will require new technologies. My daily work involves identifying innovative pathways that will enable the group to achieve its ambitions. This includes identifying potential partners among startups, university laboratories, technology providers, and more. Veolia, as an environmental services provider, plays a role in sharing concrete problems with these actors, guiding their trajectory toward solutions, and supporting them in the development and deployment of efficient processes. We have a responsibility to engage closely with these innovative actors, select the most suitable candidates, and bring their solutions to a maturity that allows for their application to our company’s activities. We can be optimistic because, in many cases, these technologies are not fictional; they are currently being developed and are advancing rapidly. During my research years at the Collège de France, I was surprised to see how quickly discovery can progress.”

What new solutions is Veolia currently deploying in the energy sector?

“The major challenge I am focused on is reducing greenhouse gas emissions, particularly CO₂ and methane—a gas that is twenty-eight times more warming than CO₂. To address this problem, there are already mature solutions, such as producing and utilizing low-carbon energies. The challenge is to deploy them on a large scale because, beyond decarbonizing specific regions, this will enable Veolia's activities in France to reach energy neutrality within five years. To achieve this, we are relying on various levers: producing more electricity and biogas from waste, installing photovoltaic panels on all available surfaces, and transforming used oils into green fuels.

“We are also developing innovative solutions for longer-term application. These involve external partnerships, such as the one established with the Collège de France and the French Alternative Energies and Atomic Energy Commission (CEA). This partnership aims to develop a technology capable of converting CO₂ into chemicals that could be reused in our wastewater treatment plants. This would create an exemplary circular economy loop at the local level.”

How is Veolia's long history an asset for the future?

“Veolia's core businesses are aligned with current societal challenges and are complementary to each other. Over time, the group has developed a decentralized model, deeply rooted in local regions, with teams who are close to local stakeholders and issues. This is a significant advantage for working toward ecological transformation. By remaining locally embedded, the ecological solutions implemented by Veolia will bring benefits to the planet and economic activity to the residents of each region.”

- RICHIT, Dominique (statements collected by MANN, Nathan) “Comment Veolia conçoit un robot de 21 mètres pour le démantèlement de Fukushima”. L’Usine Nouvelle, March 22, 2021. ↩︎